Smart LaundryManagement

Transform your laundry operations with real-time monitoring, intelligent notifications, and comprehensive analytics. Never miss a cycle again.

Explore FeaturesProject Goals & Scope

Scalable, low-cost, and non-invasive monitoring.

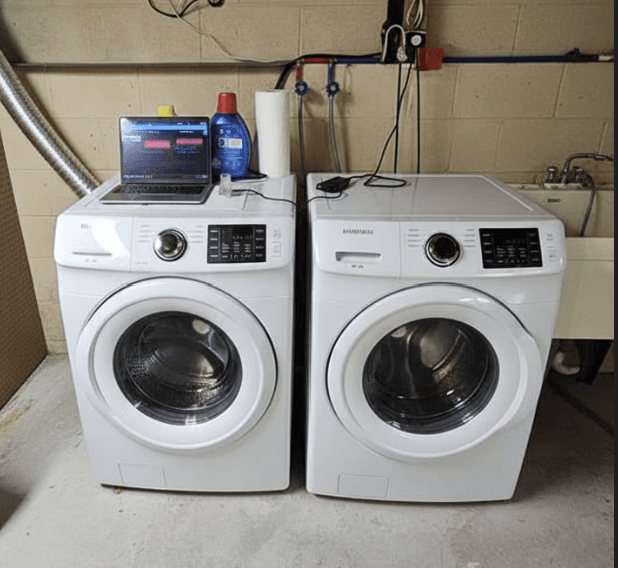

LaundryIQ was built to modernize shared-laundry monitoring using vibration and temperature sensors to detect washer and dryer activity without modifying machines.

- Core focus: live detection, uptime, and notifications.

- Deployable across dorms, apartments, and shared facilities.

- Non-invasive sensor integration with low maintenance needs.

System Architecture

Hardware → Firmware → Cloud → Dashboard

Each ESP32-S3 device collects vibration and temperature data, processed through modular firmware before syncing with Convex. The Next.js dashboard visualizes machine states in real time.

Hardware Layer

Firmware Logic

Web Dashboard

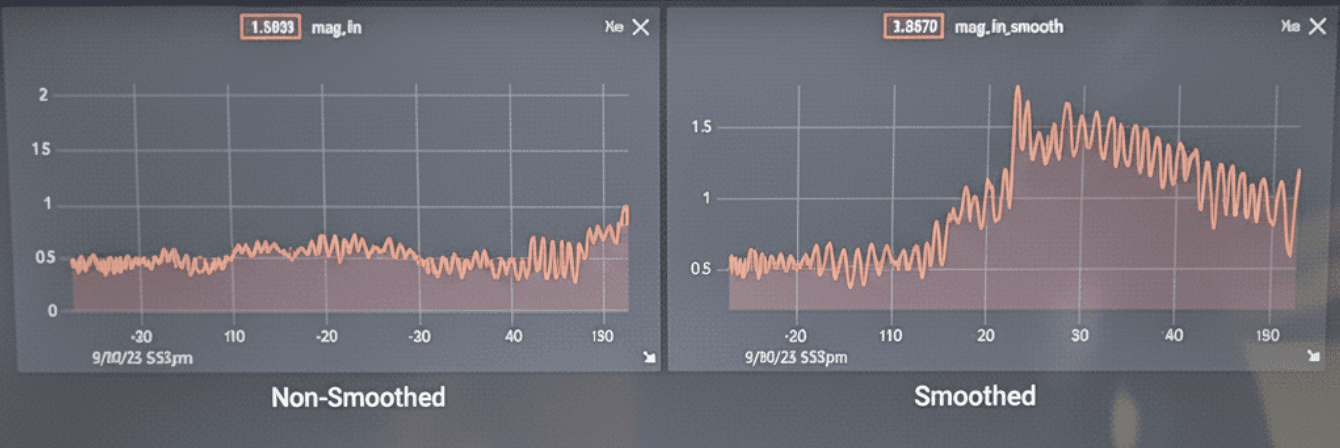

Vibration Detection & Smoothing

Turning raw IMU readings into clear, robust cycle signals.

Why smoothing?

How we use it

AI Vision Integration

Computer vision enhances detection accuracy and user experience.

Our AI vision system provides an additional layer of intelligence, reading machine displays and detecting user presence to enhance the accuracy of cycle detection and provide richer status information.

Display Recognition

Presence Detection

Hardware Reliability

Power, layout, and materials decisions for real-world installs.

Power Choice

PCB Layout Hurdles

Environmental Protection

Dashboard & Routing

Simple URLs, multi-site management, and scan-to-open access.

QR codes link directly to a machine's UUID page, so users scan to view live status instantly. Admins manage organizations and locations with readable slugs and guardrails that prevent collisions.

- Human-readable org slugs for clean, shareable URLs.

- QR codes generated to map each device to its dashboard.

- Multi-location grouping to support enterprise deployments.

Security & Reliability

End-to-end encryption, OTA validation, and tamper resistance.

Security and reliability are built into every layer — from firmware authentication to encrypted API access and hardware tamper resistance. Endpoints follow a versioned API pattern and are validated with Postman collections to catch firmware↔web mismatches early.

- Encrypted OTA and data transmission for every device.

- Strict API key protection and device authorization.

- Hardware-level tamper detection and safety layers.

Encrypted Communication

Tamper Resistance

System Reliability

A Student-Led Engineering Project

Self-directed development with structured project management.

LaundryIQ is entirely student-led, demonstrating our ability to manage a complex full-stack IoT project from conception to deployment. We created our own timeline, established clear milestones, and held ourselves accountable to deliver a production-ready system.

Self-Managed Timeline

Task Ownership

Progress Tracking

- Created detailed sprint plans with weekly goals and deliverables

- Established clear ownership boundaries for hardware, firmware, cloud, and frontend components

- Maintained accountability through peer reviews and shared documentation

- Adapted our timeline dynamically when technical challenges required pivots

- Delivered a fully functional MVP on schedule through disciplined self-management

Who We Are

Student-led full-stack IoT team.